Instantpond® Official Site: 2 Hour Build!

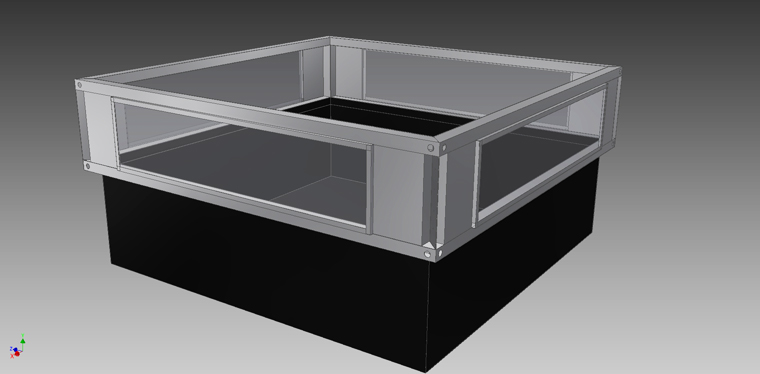

Patented - 316 Stainless Steel Ponds with Viewing Windows

![]()

-

Description

-

Bespoke Design

-

Instructions

-

Delivery

-

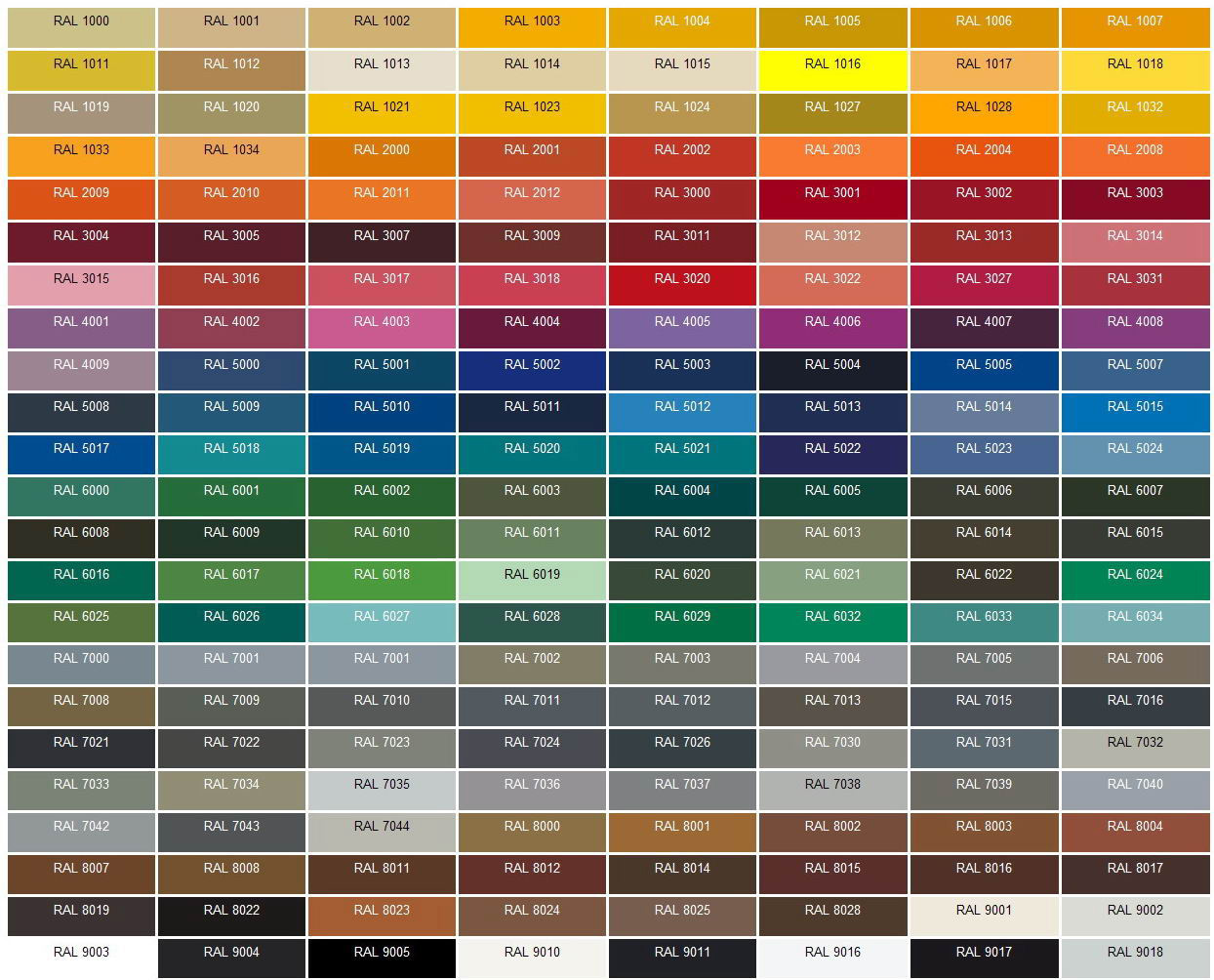

M1-M4 Style Guide

-

Additional Info

-

Contact Us

-

Pricing / Order Form

Instantponds® by Atlantica-Gardens

•Don't waste money! A beautiful pond you can take with you if you move!

•Move / Extend / Assemble / Bespoke designs

•Strong / Precision engineering / High quality components / 316 marine grade stainless steel

One of the main benefits with the instant pond now being produced by Atlantica Gardens Ltd is you don't have to leave your pond behind if you should decide to move. You can also relocate or extend your pond - and your koi will be back in their home in no time!

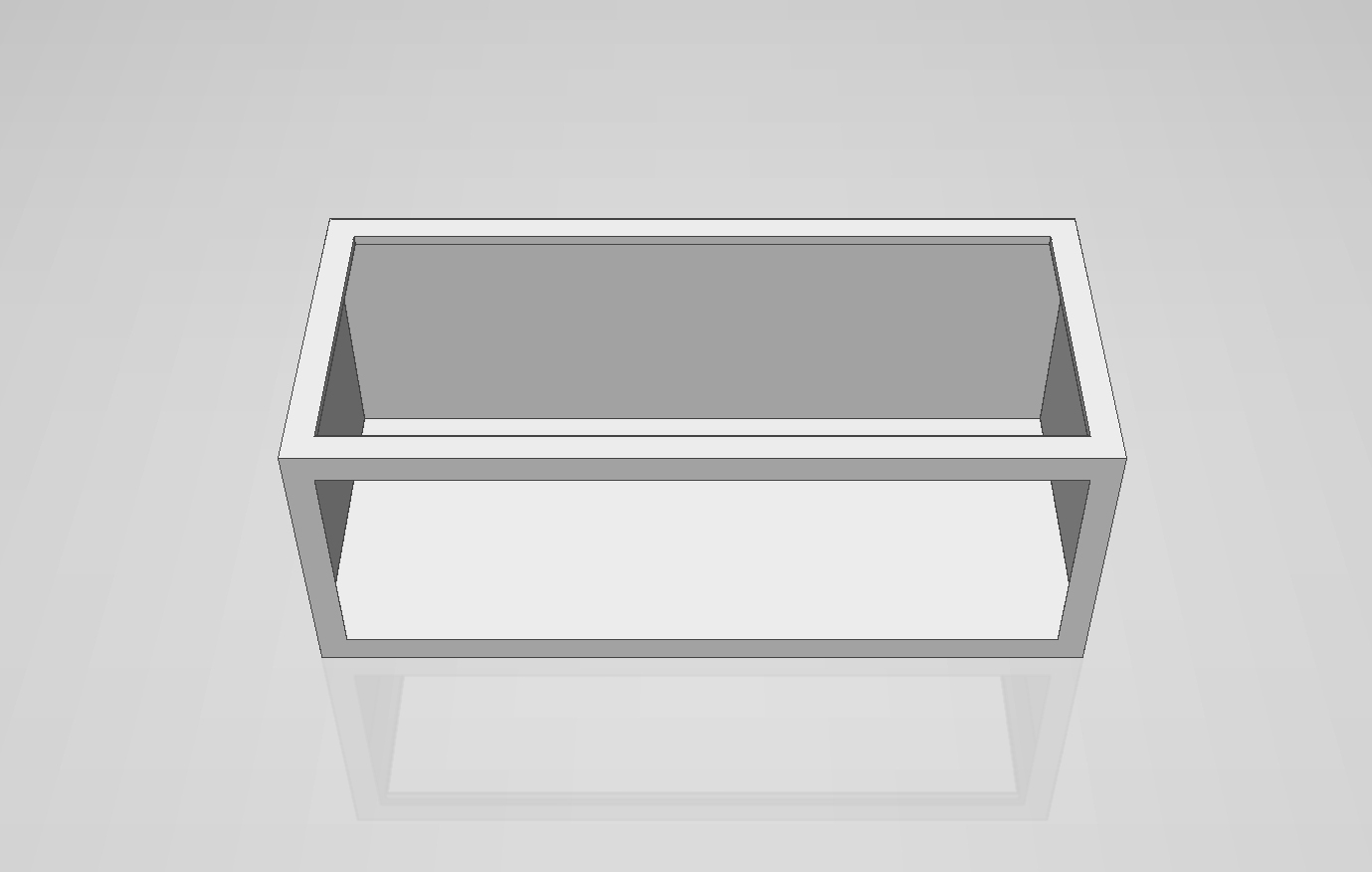

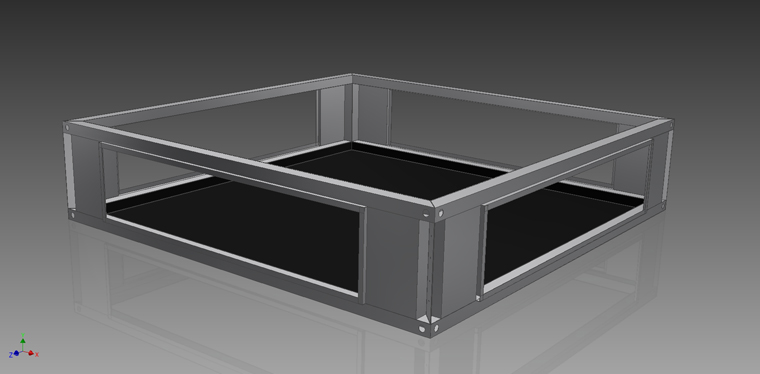

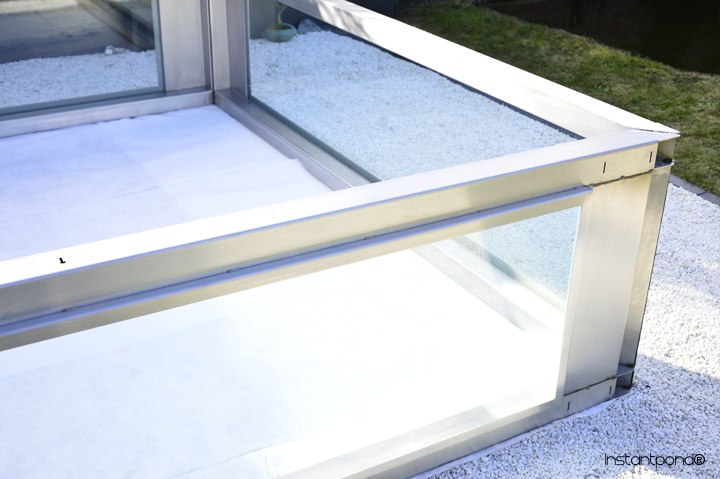

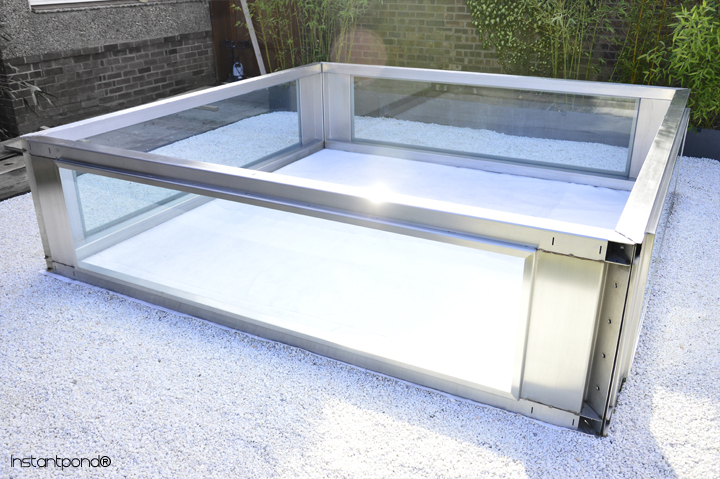

The ponds are a progression from our raised pond window frames. The ponds have the same lifetime guarantee as the frames and are laser cut from 3 mm thick 316 stainless steel, they are made to the same high standard that people have come to expect from our products.

A traditional block/brick 6 meter x 3 meter raised pond costs around £30-35,000 to have built. The Instantpond this size costs £15,000 (Brick finish, 316 stainless steel framewoork with 6 windows and below ground box liner), the stainless steel has a lifetime guarantee, looks impressive, with 6 windows you should be able to see your fish from around the garden, quickly assembled and can be moved anytime. Our customers love them!

Overview Instructions:

1. Level base (lawn, concrete, patio).

2. Align pond walls - Bolt together.

4. Seal in the box-welded pond liner.

3. Slide on side finishing components.

5. Slide on top finishing components.

6. Top up!

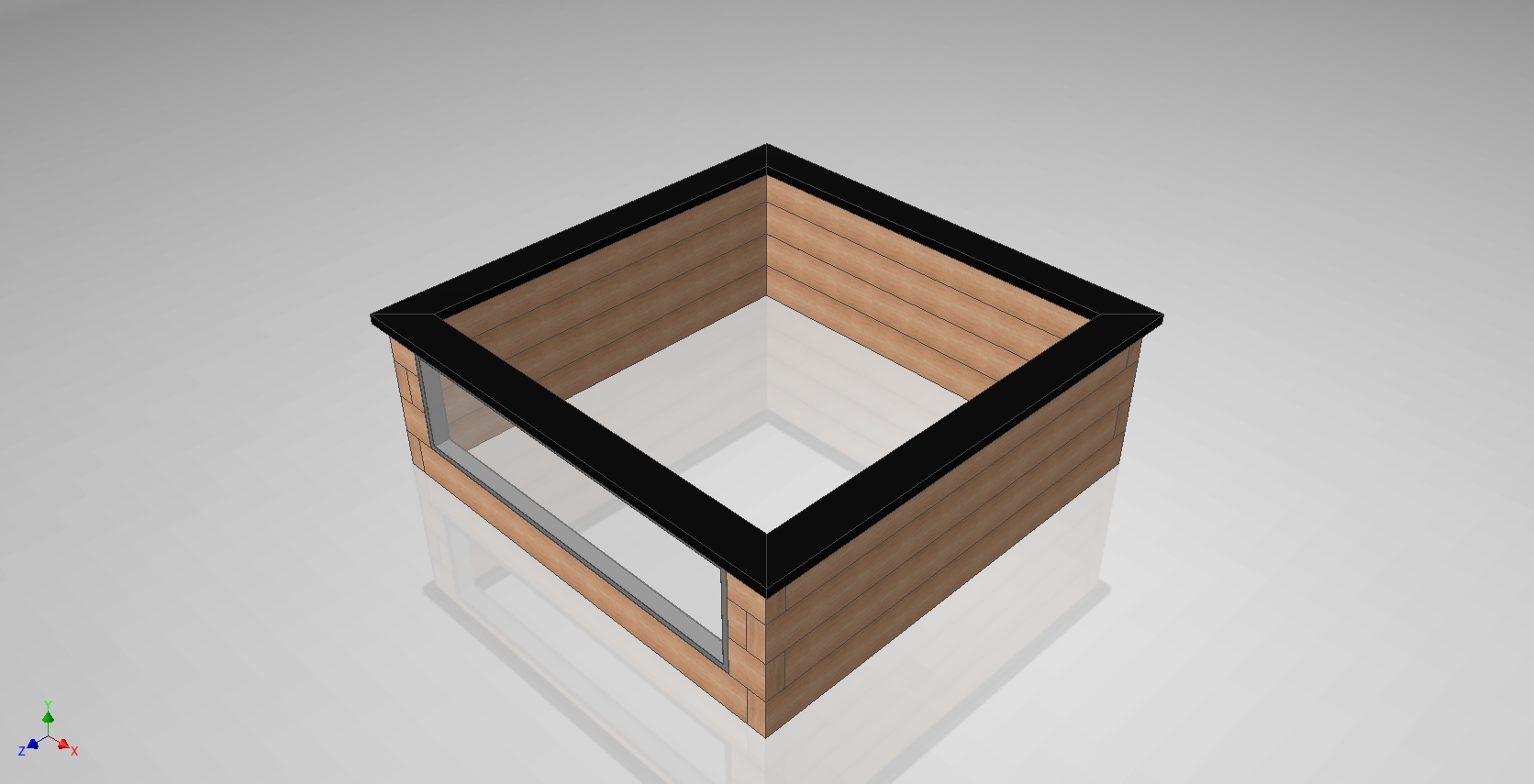

Figs 1 -3. Instantpond®-M1 | (3m x3m) Side Finishing: Real brick slips (Brunswick Red).

Top Finishing: Millboard enhanced grain (Smoked) .

• Bespoke size options: Please contact us for pricing and further information.

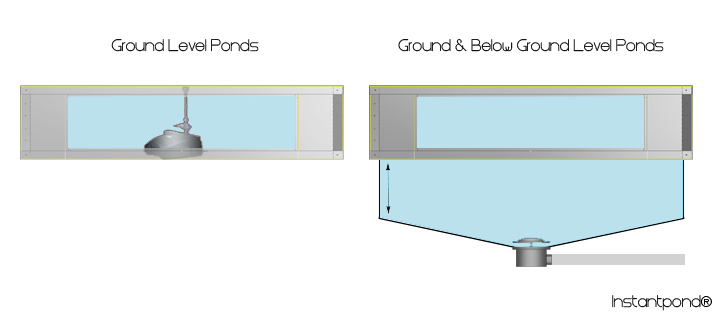

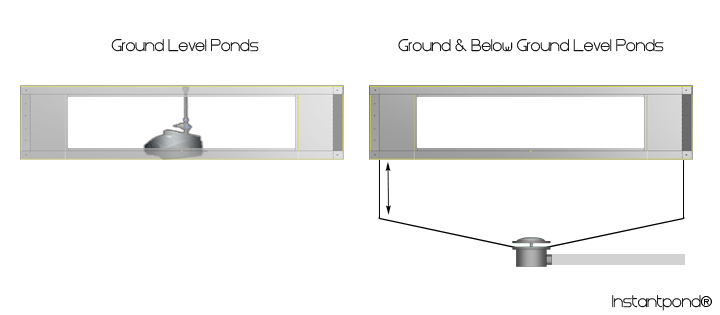

• Ground Level: 10ft x 10ft x 2.5ft pond, 1557 U.K. gallons

• Below Ground Level Example: 10ft x 10ft x 2.5ft (above) 2.5ft (below), appox 3115 U.K. gallons.

• Outside Pond Filtration

Filtration systems outside of the pond may have access for pipes through the bottom or through the side if required. The filtration would really depend on the amount of fish and feeding levels.

The advantages of our Instantpond®:

•Life time guarantee - 316 stainless steel framework;

• Quick 2 hour construction time - immediate top up;

•Assemble / Dismantle - Take your pond with you if you move;

• 10ft² (3m x 3m) stock size;

• Four 7ft viewing windows -Toughened, laminated and heat soaked glass;

• Raised pond to see fish from all around the garden;

• The base: a box-welded pond liner can also be sunken below ground - Just order your required depth of box liner.20 year guarantee.

• Custom hole positions for filtration pipes in walls. This can also go via bottom drains;

•Top & Side finishing components - 25 year guarantee ;

•If your fish get too big, you can change the size of your pond with an upgrade, by simply adding different sections and a liner.

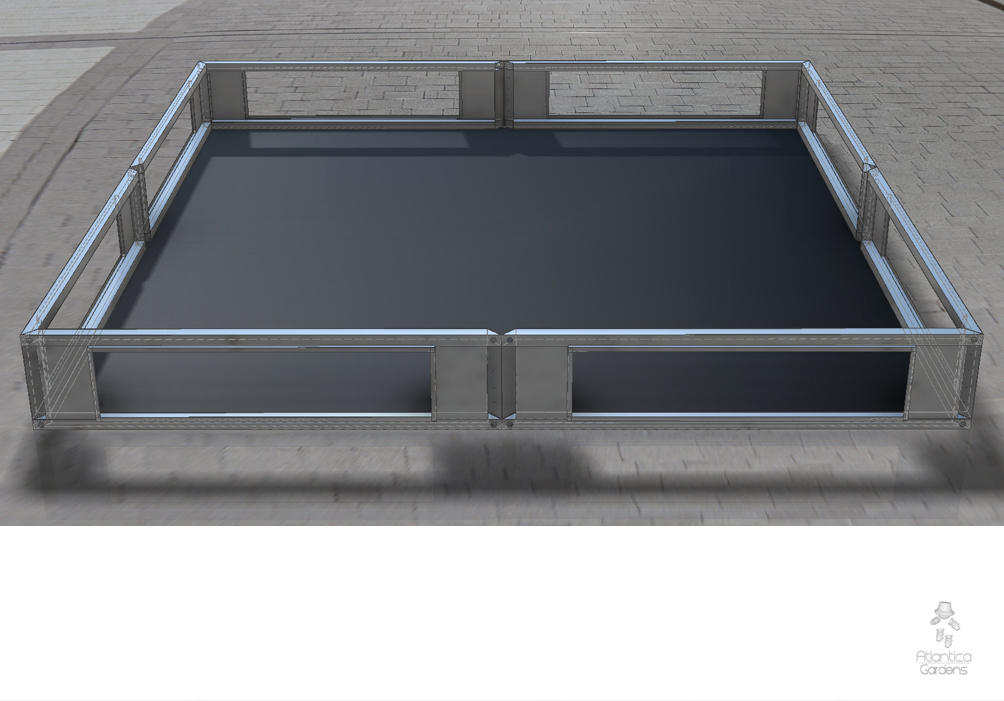

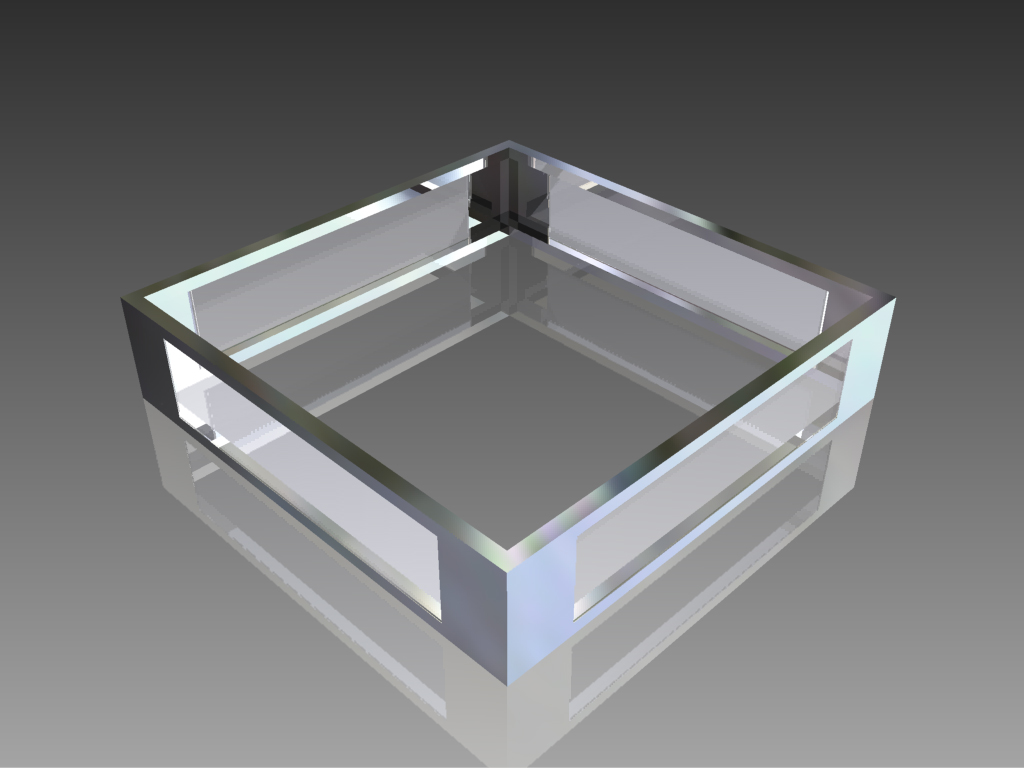

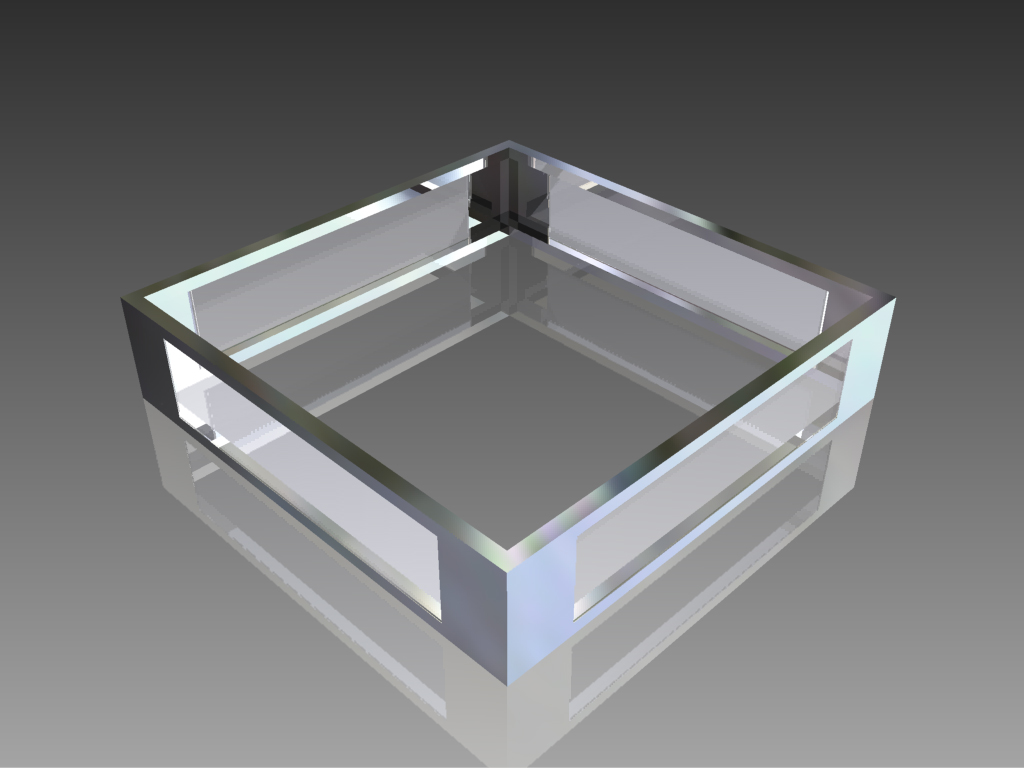

Figure above. Instantpond®-M1 | 2.4m x 2.4m | Side Finishing: Cardinal grey slate. Top Finishing: Millboard enhanced grain (Smoked)

Figs 4-6,8-10. Instantpond®-M1 | Side Finishing: Cardinal grey slate. Top Finishing: Millboard enhanced grain (Smoked).

Patent No 1501181.0

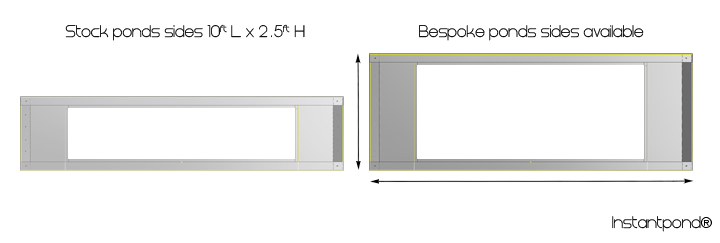

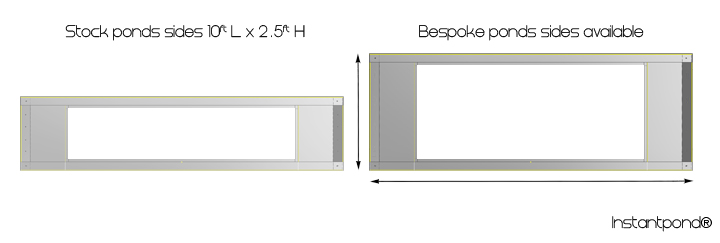

Dimensions:

• 20ft Side Wall: 6060mm L x 760mm H - 2x Glass Viewing Area : 2300mm W x 540mm H

• 10ft Side Wall: 3030mm L x 760mm H - Glass Viewing Area : 2300mm W x 540mm H

• 8ft Side Wall: 2356mm L x 760mm H - Glass Viewing Area : 1880mm W x 540mm H

• 6ft Side Wall: 1906mm L x 760mm H - Glass Viewing Area : 1300mm W x 540mm H

• 316 Stainless Steel Corrosion Free • Life Time Guarantee • For bespoke sizes please contact us.

Above Fig: Instantpond®-M1 | (6m x3m) 20ft x 10ft during fabrication before the 21.5mm glass is sealed into place.

Fig: Instantpond®-M1 | (6m x2.1m) 20ft x 7ft positioned on site ready for fiberglass. Clad with cheddar brown ibstock brick slips.

Base:

• Level with ground or below ground. The instantpond just needs a solid foundation (e.g concrete base), and a ring beam depending on the depth.

• SealEco EPDM box-welded pond liner from Gordon Low • 20 year Guarantee.

• Full stainless steel base available. please contact for more details and pricing.

All depths of box-welded liners available please enquire. For ponds not requiring a pond liner e.g a fiberglassed base please enquire for more information.

• Ground Level: 10ft x 10ft x 2.5ft pond, 1557 U.K. gallons

• Bcelow Ground Level Example: 10ft x 10ft x 2.5ft (above) 2.5ft (below), appox 3115 U.K. gallons.

Ground Level Box-welded Liner Base 10ft x 10ft

3ft Below Ground Level Box-welded Liner Base (Total Depth 5.5ft) 10ft x 10ft Side Frames.

Top Finishing Components:

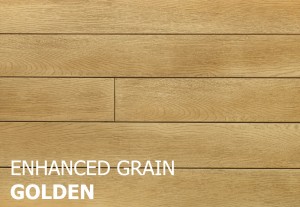

Millboard enhanced grain collection

With its smoother, wood-grain finish, the Millboard enhanced grain collection, available in five distinctive colours will add style and elegance to any project. Whether it is the contemporary inside/outside look, alfresco room or the classical deck, our Enhanced Grain will add elegance and style to any project.

• Environmentally Friendly • Maintenance Free • All enhanced grain boards: 176mm W x 32mm H • 25 year Guarantee

1.  2.

2.  3.

3.

4.  5.

5.

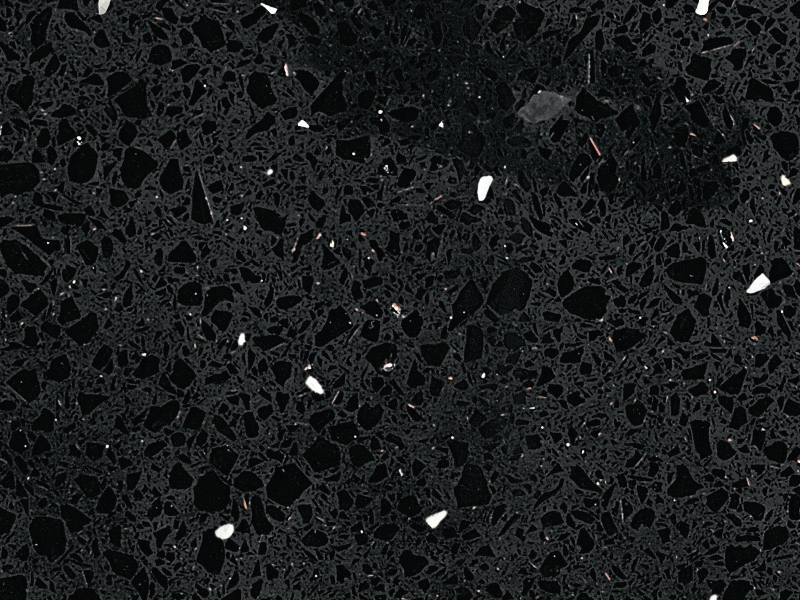

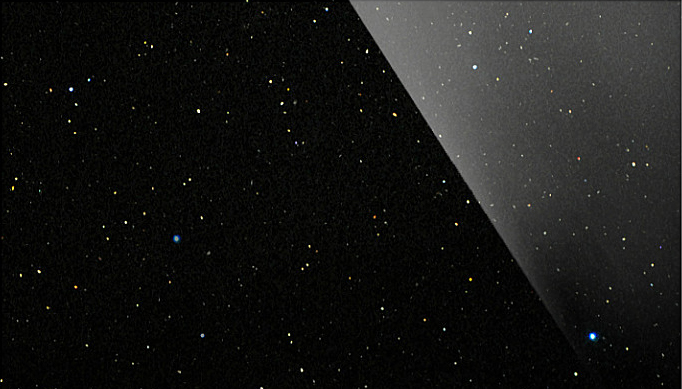

Granite / Quartz collection

Granite: 100% natural. The granite slabs are sliced from quarries, cut to size, and honed down until they are smooth.

1.

1. Black Starlight Granite

Quartz: 97% natural. Prominent quartz 93% natural quartz aggregates are mixed with the remaining 7% of color pigments and polymer resins. The resins bind the particles together.

1.  2.

2.

1. Black Mirror Quartz

2. White Mirror Quartz

Side Finishing Components:

Ibstock Brick Slip collection

Excellent durability and low maintenance of natural clay.Environmentally sensitive and sustainable manufacture to BS 14001. Slip Bricks match the equivalent standard brick for colour, size and texture. There is a wide choice making matching existing buildings easy.

• All brick slips: 215mm L x 65mm W x 20mm H • Pre-fixed to frames and carriers ready for instant construction • Please note that other sizes of slips may not fit the dimensions of the pond. • 30 year Guarantee.

1.  2.

2.  3.

3.

1. Brunswick Red

2. Atlas Smooth Blue

3. Oyster White Waaldik

For custom brick slips please enquire for availability and price. To view more options please follow link to ibstock: brick selector.

Slate Tiles

1.

• Spanish Cardinal Grey Slate - Premium A1-S1-T1 • 50 year Guarantee.

Filtration:

In Pond Filtration

Filtration can be done from inside the standard 10ft x 10ft ponds with the Oase all in one type of pump, filter and UV (2 x Oase Filtral 9000 UVC Pond Filter).

Multiple Filtral 9000 units can be used in larger ponds, offering multiple points of suction, circulation and UV clarification (i.e. 2 x Filtral 9000 units will suit a pond volume of 18000 litres without fish, or fish ponds up to 9000 litres).

Outside Pond Filtration

Filtration systems outside of the pond may have access for pipes through the bottom or through the side if required. The filtration would really depend on the amount of fish and feeding levels. Please contact us with your requirements.

1.  2.

2.

1. Pipe welded into position as requested by customer. 2. Holes placed within the side of the pond for use with a Oase Tradux system. Please contact us with your required placement and number of outlet/ inlets required.

--

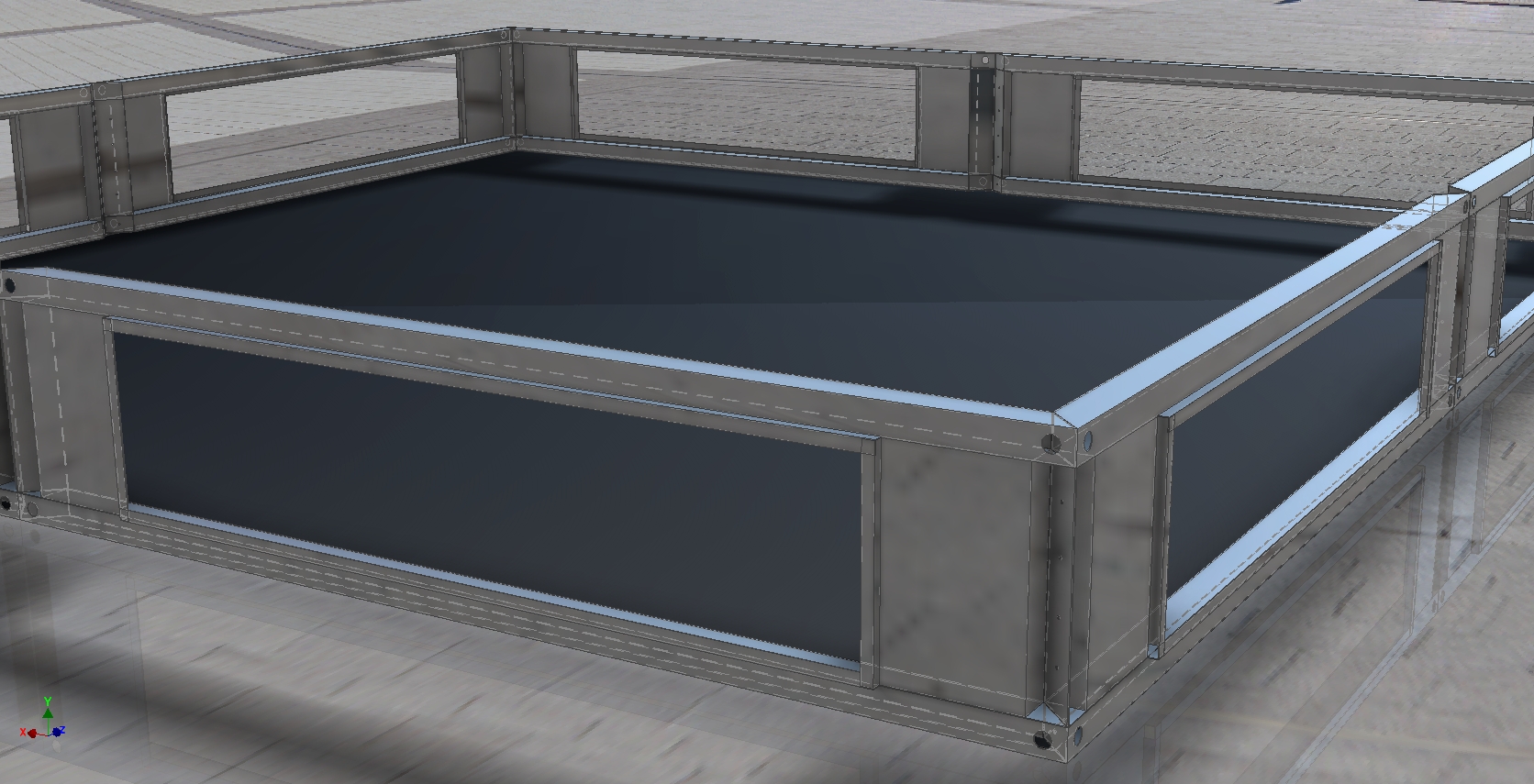

--

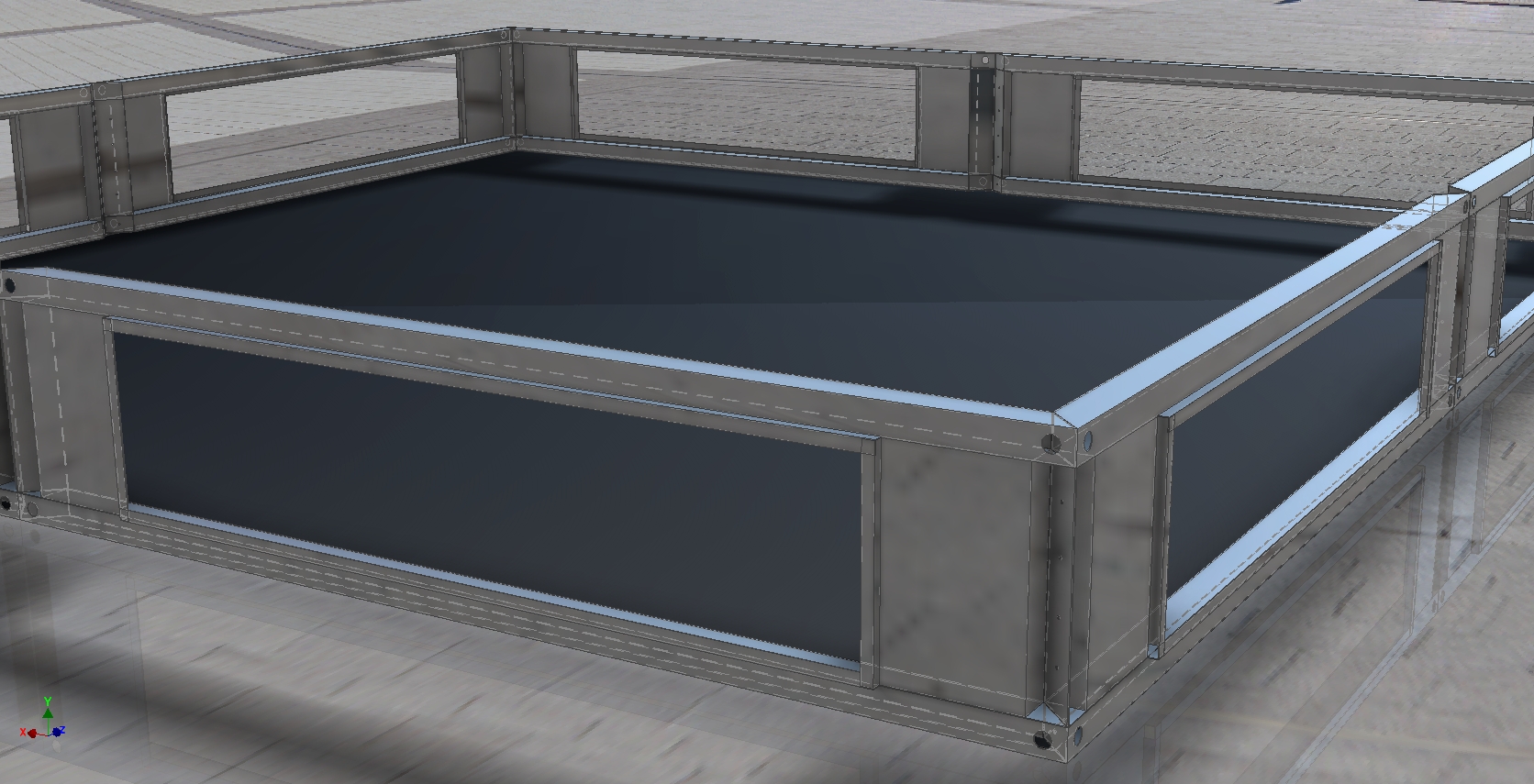

Figures above shows an Instantpond®-M2 | (2.4m x2.4m) 8ft x 8ft during construction. The pond was fabricated to the requirements of the customer with three 65mm holes for their filtration system to neatly exit the pond.

• Videos

Video: The Instant Koi Pond

Video: Assembly Part 1: Positioning the Framework.

Video: Full Assembly.

Order Forms:

• We accept card payment though PayPal via our order form. For custom orders please email with your desired design.

• Alternatively we accept bank transfer payments. For this option please contact us on +44(0)1255 814101 or contact@atlanticagardens.com

• Please contact us for bespoke shapes and sizes. Contact Form

* Other pond styles and sizes are available please view our Shop

**International Delivery: Please phone / email with your address for a detailed costing and service. Thank you.

_ _

Please view the next tabs for: Bespoke Designs / Instructions / Postage / Order Form & Prices / Additional Info

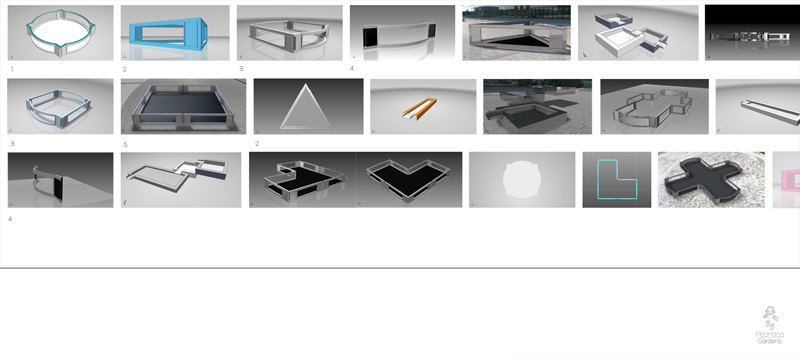

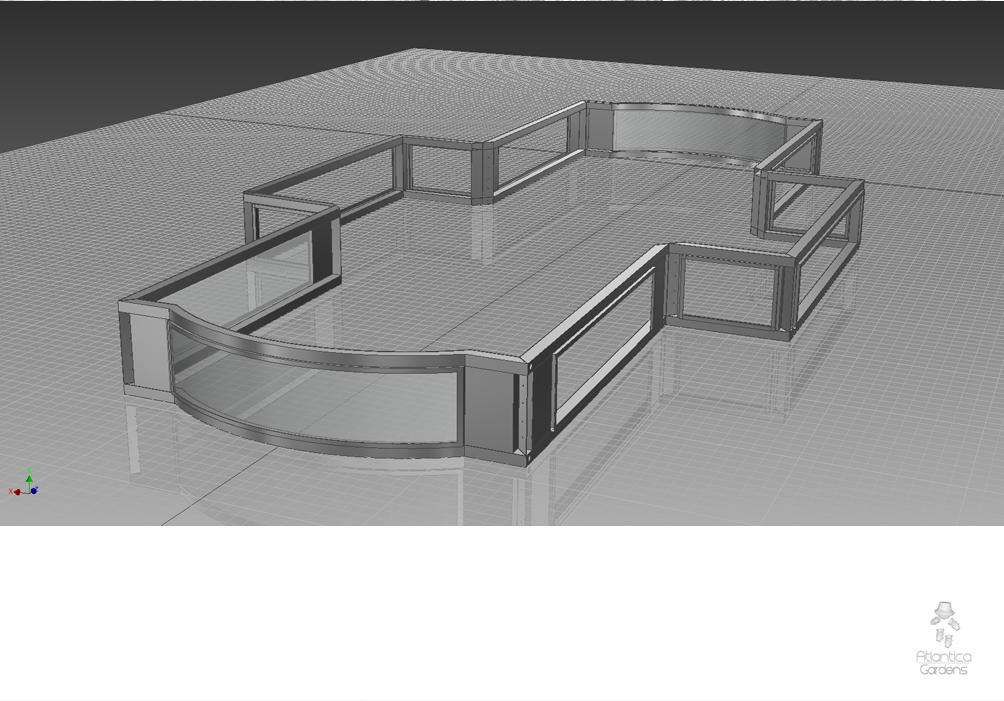

Bespoke Design:

• Curved End Instantpond®

• Fully covered brick slip/ tiled side Instantpond®

• 20ft² Square Instantpond®

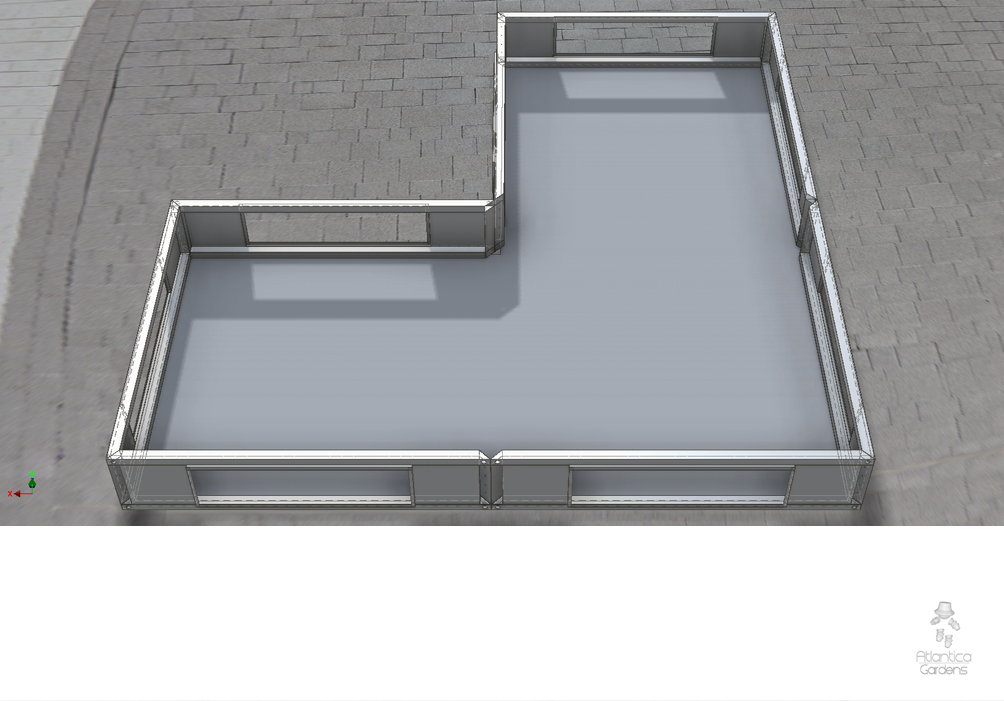

• L-Shaped 20ft Instantpond®

• Instantpond® with freestanding pond wall

For all custom designs please contact on 01255814101 for further details.

Courtyard instantpond design for customer includes filtration box and freestanding pond wall with three waterfall blades.

Bespoke designs shown: Patent No GB1501181.0

_ _

Please view the next tabs for: Instructions / Postage / Order Form & Prices / Additional Info

Overview Instructions:

1. Level base (lawn, concrete, patio).

2. Align pond walls - Bolt together.

4. Seal in the box-welded pond liner.

3. Slide on side finishing components.

5. Slide on top finishing components.

6. Top up!

Fully Detailed Instructions:

Each pond is sent out with full instructions. Please read all the instructions carefully before commencing. If you have any questions please contact us on 01255814101. (Assembly video in progress).

1. General preparation for the pond area:

If your intended site has firm soil then you will just need to level the area for the frame and the liner. If you have unstable crumbly soil you may need to put a firmer base down. If you are going to put the pond onto bricks or slabs so that you can cut the grass around the pond, you will need to level them so the frame has a flat surface to sit on. If you are having a deeper below ground box liner make sure when you lay your bricks/slabs they do not go inside the frame as this will give an uneven area for the box liner walls. Alternatively you can cut a small trench, with the inner edge in line with the inside of the frame. this needs to be about 4" deep and about 10" wide to go all around the perimeter of the pond and fill with an 8 - 1 sand/ballast cement mix and level.

--

--

Figs. 1-2: Level patio height with the base.

Fig 3: Below ground foundations using a box-welded liner.

2. Alignment (Fixing of the pond walls and locking):

• You are now ready to place the first section of pond wall into position. This will need steadying until you have bolted the next section to it. The second section should be placed against the first, with the corners touching and pond walls at 90 degrees to each other Fig. 1.

• The frames have two 10 mm diameter location holes at each end Fig. 2. Use the supplied tapered rods in the the 10 mm holes to align the frames, see Fig.2, so that the clamping bolts can be fitted. The six bolts and washers for each corner joint have collars of the correct length so when the nuts and bolts are fully tightened the neoprene seal will be compressed between the corner joint. The bolts, with washers and collars, should be placed into the holes through both frames so that the washer under the bolt heads fit flat against one frame and the collar on the bolt can be seen through the hole in the other frame, see Fig.3. Place a washer and nut onto the thread. The nuts and bolts should be hand tightened only at this stage to allow for any adjustment if needed when you later check diagonals, so that your pond will be square and the seals will be flat against the flanges.

Figs. 4-6: Align the 316 stainless steel frames.

• The measurement across the diagonals of the pond (without top finishing components) is 5376 mm. Once you have the right measurement you can repeat the process for the next side. Make sure that side 1 and 3 are parallel, if not, only move side 3 as 1 and 2 are now set. Side 4 can be put in position and held while the location pins are put in the two holes of corner joint three, lightly screw the 6 bolts, nuts and washers together. Check both diagonals are the same, if any adjustment is needed ease the longer diagonal in to make them the same. You can now tighten all the bolts in turn one turn at a time, checking diagonals as you go until the nut and bolts are tight, the washers will tighten down on the bolt collars, so no need to over tighten (19Nm (37ft lb)).

Fig. 7: Hand tighten stainless steel bolts.

Fig. 8: Fully tighten stainless steel bolts to 19Nm (37ft lb).

3. Sealing of the corner joints:

• It is easier to put the underlay and liner in position before you seal the corner joints. Place the underlay in position, it should fit snugly into the bottom corner of the side frames remove any excess with scissors.

• On the ponds that are having a liner positioned level with the surface, layout the liner with the lip facing upwards,

With deeper box liners the tags will be the right spacing down from the top edge. Push the liner corner tags through the gap at the bottom of each corner under the black neoprene gasket, once through, gently pull into position from the outside. These tags once fitted into the securing slot should be turned at 90 degrees to lock into position, as shown in the video and fig 715. The securing slot is on the outside under the bottom frame clamping bolt, on the right hand clamping flange.

• The side frame joints will have been pre taped down each corner, you will notice the back neoprene gasket set back sightly in the corners, this is to allow for a good bead of polymer to fill the corner. Place a piece of wood on the corner of the liner to keep it down out of the way when you apply the polymer to the corner joints.

• You should apply enough polymer so that once smoothed out, the polymer will reach the tape on either side of the joint. We use the end of a polymer cartridge for smoothing out, once a smooth seal has been formed all the way up you can remove the tape and clean the cartridge of polymer ready for smoothing out the next corner. If the polymer starts to drag use clean water in a sprayer to mist it over and try again with a cleaned cartridge.

--

--

Figs 9-10: For a quicker top up time fill the corner with fiberglass first before using polymer for a water tight seal.

--

--

Figs 11-12: Sand the fiberglass to key then apply masking tape before using the polymer.

Fig. 11: Sealed corner joint with white polymer for demonstration purposes. Final product uses clear Aquamate Goldseal polymer..

4. Sealing of the pond liner:

• The liner is in position being held with the tags, remove the wood that you placed in the corners to hold the liner

• Apply an 8 mm bead of polymer in the position shown on the video, about 25 mm down from the top of the beam. Start where shown just before a corner , so that when you have gone all the way around you can just pull the liner away slightly and go over the first flattened bead of polymer with another application to make sure there is a continuous seal. We use a wallpaper seam roller to gently flatten the polymer as you go, if you roll it out to 1 - 2 mm thick it will give a wide bonding surface between the liner and the frame, care should be taken not to stretch the liner as you may then end up with excess liner when you reach the next corner.

---Figs. 12: Sealing the box-welded pond liner.

--

--

Figs. 13-14: Seal the liner by applying polymer to the bottom flange on ground level instantponds the sealing flange will protrude from the framework. Place the polymer so that it is facing upwards, push the liner into place and lastly apply polymer into the corner.

5. Attaching the side finishing components:

Fig 15: Brick slip carriers lugs and frame securing slots.

----

----  ---

---

Fig 16: Slide brick slip carriers into securing slots; Figs 17-18: lower into finished location.

Fig 19: If applicable - Slide middle brick slip carriers into securing slots.

6. Attaching the top finishing components:

• One of the coping securing plates that is on the left hand end of the coping has a slot, this is to correspond with a cutout in the right hand end of one of the copings and should be positioned on the corner that would be used to enable pump cables or air stone tubes to enter the pond unnoticed and be adjacent to an electrical supply. The electric cables should be fitted by a qualified electrician and be to the regulations for your area.

Fig 20: Slide top finishing components onto frames.

Fig 21: Slide top finishing components into the keyhole slots.

Fig 22: Attach the top finishing component corner joints.

To dismantle the instant pond please view the following instructions video:

Please contact us if you need any more information on 01255814101 or contact@atlanticagardens.com.

_ _

Please view the next tabs for: Bespoke Designs/ Instructions / Postage / Order Form & Prices / Additional Info

UK Delivery Information:

Zone 4 Republic of Ireland £365

UK destinations are sent on a next day delivery service with APC-Overnight.

Lead time is currently 6-8 weeks from date of purchase (unless in stock at time of ordering) + delivery time.

Netherlands - (Example price to Amsterdam) TNT 2 day air freight service is £400.00 VAT inclusive

Germany / France / Belgium - (Stuttgart) TNT 2 day air freight service £456.00 VAT inclusive.

United States of America - (New York) TNT 7-10 day air freight service £1180.00 VAT inclusive.

A standard Instantpond® is delivered ready for construction comprising:

• Four 316 stainless steel walls - containing four toughened and laminated glass viewing windows;

• SealEco EPDM box-welded pond liner base;

Finishing components:

• Eight 316 stainless steel side plates containing brick slips from the Ibstock brick slip collection;

• Top copping from the Millboard enhanced grain collection.

Construction components:

• 316 Stainless steel nuts, bolts and washers;

• Neoprene gaskets;

• Sealant;

If you require installation please contact us.

_ _

Please view the next tabs for: Bespoke Designs/ Instructions / Postage / Order Form & Prices / Additional Info

M1 | Instantpond®:

•Bolt together.

•Interchangeable finishing components (Real Brick / Slate / Granite).

•Extend / assemble / dismantle as many times as you like.

•One to four windows (more if 20ft long). No price difference if less windows.

• One hour construction time.

_

_

M2 | Instantpond®:

Similar to the luxury version shown throughout this page this version has the following attributes:

•Bolt together.

•Smooth powder coated finish (No additional finishing components such as coping (But can be fitted if required)).

•Window housing (Glass) does not protrude from the outer surface.

•Larger glass viewing area than the Luxury version above.

•Extend / assemble / dismantle as many times as you like.

•One to four windows (more if 20ft long). Prices start with one window and increase as additional windows are included.

• One hour construction time.

Figure 1. Please select your colour code and specify at checkout when purchasing.

_

_

Figs 4-5. Instantpond®-M2 | (2.4m x 2.4m) 8ft x 8ft. Side Finishing: Powder coated (Teal)

Other Ranges:

M3 | Small Modern Pond:

•Typically smaller than the ranges above.

•Usually only requiring one glass window.

• Simplistic design.

• No setup required, delivered finished.

M4 | Wooden Sleeper Pond:

•Comprises of oak or softwood railway sleepers.

• One window frame patented design for wooden ponds.

• Four hour construction time.

_ _

Please view the next tabs for: Bespoke Designs/ Instructions / Postage / Order Form & Prices / Additional Info

Please find the Frequently Asked Questions section at the bottom of page. Thank you.

Frequently Asked Questions:

The following is for guidance only and does not affect the Terms and conditions. We try to give as much information as we can across the site but if you have any further questions regarding our products or services we would be very pleased to help.

• How easy is the pond to maintain?

With the right filtration and UV light to keep the algae in check, and you don’t overstock, it should be a simple matter of just cleaning the glass.

• How do you clean the windows?

We use a rubber blade type window cleaner (Squeegee) with an extension handle.

• Can you fit a bottom drain?

On the 3 meter square koi ponds the liner has a natural sag, so if you have your pond sited on soil you can angle the soil down 100mm towards the centre. Position the bottom drain so that the clamping flange will be level with the liner. Fill around the bottom drain and pipework with sand and firm.

• How does the water come back into the pond?

The returning water can either be by a baki type filter or conventional filter and then pumped back via a water feature/ water fall blade.

• Overwinter precautions for a raised koi pond?

• Is there any access for electrical cables?

There is provision for cables and tubes for an air stone if required to enter the pond behind the right hand side brick slip pillar. You will notice that one of the coping joining brackets has a cut out that will go over the plastic conduit that houses the cables and tubes, the joining coping will also have a corner cut away to miss the cables.

The pond should be positioned so that the corner with the cut-outs will be in the finished position to facilitate connecting to a power supply. This should be to the regulations covering your particular area and be installed by a qualified electrician.

• Can I have my own finishes?

We will if possible try to accommodate your choice of finish. Please enquire before ordering if you would like a particular finish or a certain brick as they may not be compatible with the dimensions of the pond.

• Are they real bricks?

We use real bricks that are wire cut to 20mm thick from the ibstock collection.

• How large can I have a bespoke Instantpond®?

For the larger ponds you will need buttress sections that will give stability. Please see the cross design in bespoke designs, which shows the buttress sections. There is no real limit to size at the depth of the standard Instantpond.

• How easy is it to extend an Instantpond®?

It’s very easy to extend your koi pond.

Overview:

Pump out pond.

Remove liner.

Remove coping and brick slips.

Remove the required pond wall sections. If you are removing all of the wall sections care should be taken to support the last two sections as they are unbolted.

Clean all joints, prepare base and fit the new sections following the instructions, as these will vary, we will send out instructions for your particular build.

If you watch the video section on how to dismantle your instant pond you will see a section on how to remove the liner. You will only need to remove the brick slip carriers, coping and the required pond wall sections from the area being affected. We will send you detailed fitting and removal instructions with the new pond sections.

All the instant ponds are laser cut and formed so will be a perfect fit onto your original pond sections. Care will need to be taken that the new extended area for the pond will be on a suitable base, compatible with the base of your original pond and that it is inline and level with the original pond base.

_ _

Please view the next tabs for: Specification / Instructions / Postage / Order Form & Prices / Additional Info

We try to give as much information as we can across the website but if you have any further questions regarding our products or services we would be very pleased to help.

Contact

Atlantica Gardens Ltd

19 The Chase

Holland-on-Sea

England, CO15 5PU

Telephone +44 (0)1255 814101

email: contact@atlanticagardens.com

email: sales@instant-pond.com

URL: instant-pond.com

About

Richard Clapham (*1950) and Richard James Clapham (*1985) started Atlantica Gardens Ltd in 2004 developing koi pond window frames and distributing across the UK. Instant-pond.com was founded in 2015 to showcase and launch our newly developed product the instantpond®.

Copyright

All work is © 2004 – by Atlantica Gardens Ltd

Website by Atlantica Gardens Ltd

Terms & Conditions

All rights resevered. Please ask for permission before using images for commercial websites.

_ _

Please view the next tabs for: Specification / Instructions / Postage / Order Form & Prices / Additional Info

Please choose your design: M1 | M3 | M3 | M4

M1

M1  M2

M2

Order Forms:

• We accept card payment though PayPal via our order form. For custom orders please email with your desired design.

• Alternatively we accept bank transfer payments. For this option please contact us on +44(0)1255 814101 or contact@atlanticagardens.com

Modern Ponds Learn More...

*Please choose:

| Delivery Destination |

Wooden Oak Sleeper Ponds Learn More...

• We accept card payment though PayPal.

• Alternatively we accept bank transfer payments reducing total price by 4%. For this option please contact us on +44(0)1255 814101.

• Refund and Returns Policy: Our stainless steel frames have a lifetime guarantee against corrosion and faulty workmanship. Other components sold online by Atlantica Gardens Ltd will be replaced free of charge if found to be supplied in a substandard condition or not as ordered.